-

IEC 62368 Test Equipment

- IEC60529 IP CODE TESTING...

-

IEC60335-1 Testing equip...

-

Flammability Test Chambe...

-

IEC60884-1Testing Equipm...

- Accessibility Probes

-

Impact Testing

-

IEC60061-3 lamp gauge

-

Electric Safety Tester

-

Environment Test Chamber

-

UL Testing equipment

-

LED Test Instruments

-

Plug, Socket & Switch Te...

-

Oscilloscope

-

Electronic Components Te...

-

Force Meter

-

Tensile Testing Machine

-

Other product

-

Plug and Socket Gauges

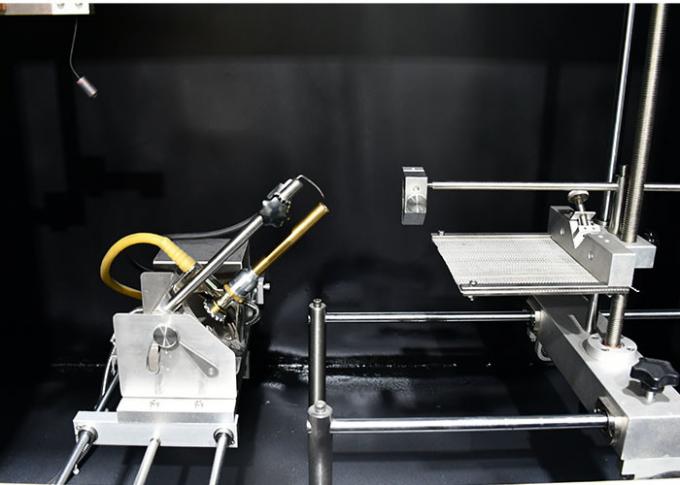

IEC60335-1 clause 30 Horizontal And Vertical Burning Test Apparatus

Product Information:

This test apparatus is designed and manufactured according to the standard requirements of IEC 62368-1:2018 Annex S, IEC 60950:2013 clause 4.7.3, IEC60065:2014 clause 14.1, 20.2.1, 20.2.4, Annex G, IEC60335-1 clause 30, etc. It simulates the influence of early-stage flame when there is a fire around the electric and electronic products, so that to judge the igniting danger degree. It is mainly used in plastic and other non-metallic material sample, solid material. It is also applicable in the Horizontal, vertical flammability test of the relative combustion characteristic of foam plastics whose density is no-less than 250kg/m according to ISO845 test method. It is also applicable in the Horizontal, vertical flammability test of the relative combustion characteristic of foam plastics whose density is no-less than 250kg/m according to ISO845 test method.

This series of products adopt integral type inlet ignition system. The combustion time delays 0.1S thus to make sure the sufficient time of gas burning. They are with matte black background, multi-functional flame measure gauge, stainless steel of box full, large observation window, imported digital indicator of high precision, nice appearance. And they gather a number of advantages of similar products home and abroad.

Technical Parameters:

IEC60695-11-3/IEC60695-11-4/10, UL94, etc.

50W:10mm;

50W: 0°,45°;

Applied standard

IEC 62368-1

Clause

Annex S

Working voltage

220V/50Hz

Power/grade

50W and 500W double power switching

Control operation mode

PLC control, 7-inch color touch screen operation, with infrared remote controller

Blast burner standard

inner diameter:Φ9.5±0.3mm,length:100mm,made of brass

Gas pressure

0.1MPa

Gas flow

50W:105±5ml/min or 18±1mm;500W:965±30ml/min or 117±3 mm,flow meter adjustment

U type pressure gauge back pressure water column height

500W:125±5 mm

Test angle

500W: 20°

Burning time

0-9999X0.1S Can be preset

Burning times

0-9999 times,Can be preset

Residual flame/Residual glow

0-9999X0.1S Can be displayed

Test flame calibration

Temperature measuring copper head:50W:Ф5.5mm±0.01mm,weight before drilling 1.76 ± 0 .01 g;500W:Ф9mm±0.01mm,weight before drilling 10 ± 0 .05g

Thermocouple: The American original Omega φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple, temperature resistance 1100°

Distance between the bunsen burner port to temperature measuring copper block:50W: 10±1 mm; 500W: 55±1 mm

Flame height:50W: 20±2mm(there is no internal and external flame); 500W: Inner flame:40±2mm,Outer flame:125±10mm

Temperature rise time from100±2°to 700°±3°50W: 44±2S; 500W: 54±2S

Lighting

Equip with lighting in the test chamber, with control

Test chamber and dimension

> 0.75 cube, black inwall, with exhaust fan, dimension:1100*550*1200mm, 140kg